At Porta, our facilities are the foundation of the trust we’ve built over generations. Each site is engineered to deliver world-class products through innovation, reliability and local expertise. We create skilled jobs, support regional communities and invest in technology that keeps Australian manufacturing strong. With a focus on sustainability and progress, Porta is building for the future – one facility at a time.

From recycling to new products, we keep resources in use.

Timber from certified plantations and accredited suppliers.

Investing in renewable energy and efficient processes to reduce waste.

We invest in local jobs and support the communities where we live and work.

Driven by innovation and responsibility, we act today to impact tomorrow.

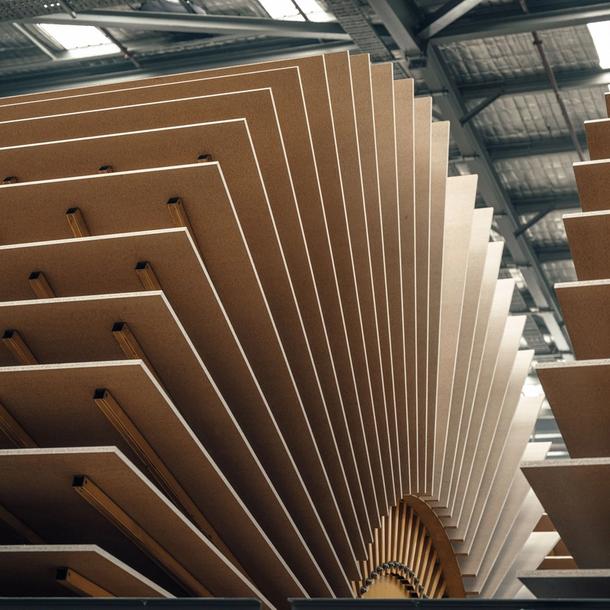

Our Oberon facility is an advanced manufacturing site producing particleboard and MDF panels that underpin Porta’s structural and decorative product ranges. It is also home to Australia’s largest rooftop solar PV system (10 MW), reflecting our ongoing commitment to sustainable manufacturing. Oberon supports local jobs, drives regional growth and creates long-term opportunities across trades, transport and services.

Our Somersby facility is a hub for innovation and finishing excellence, specialising in value-added timber products such as laminated panels, decorative finishes and engineered solutions. With deep community connections, the site is a major employer on the Central Coast, driving regional prosperity and providing stable careers in manufacturing, logistics and technical roles.

Soon to be our newest and most ambitious facility, Mount Gambier is a state-of-the-art site designed to meet Australia’s growing demand for MDF and particleboard. Representing one of the largest investments in regional manufacturing, the site continues to expand its capabilities, driving innovation and sustainable production.

The facility will continue to create local jobs and deliver long-term benefits to the Limestone Coast community, reinforcing Porta’s commitment to regional growth, local employment and sustainable Australian manufacturing.

Located in the Snowy Monaro region, our Bombala facility transforms sustainably sourced Radiata Pine into a wide range of building and landscaping products, including structural timber, decking, preservative-treated sleepers and fencing solutions. Each product is engineered for durability and performance, delivering strength and reliability to projects across Australia.

As one of the region’s largest employers, Bombala provides long-term stability and opportunity for the local community, supporting families, suppliers and regional businesses. The site reflects Porta’s commitment to sustainable manufacturing and to driving economic growth in regional Australia.

Our Bridgewater sawmill, located just north of Hobart, is the heart of Porta’s Tasmanian Oak milling operations. The facility manages the milling, grading and preparation of sustainably sourced Tasmanian Oak, supplying high-quality hardwood for use across Porta’s timber moulding range.

As a long-standing regional employer, the Bridgewater site plays an important role in supporting local jobs and developing skills within the community. With a focus on efficiency, resource recovery and reuse, and responsible production powered by solar energy, the mill reflects Porta’s commitment to Australian manufacturing and sustainable resource management.

Our new Epping facility is the heart of Porta’s timber mouldings production. Relocated from our historic Fairfield site, the facility represents both our heritage and our future, combining decades of experience with modern manufacturing capability.

At Epping, we produce Porta’s full range of timber mouldings, along with dowels and handrails trusted by builders, suppliers and trades across the country.

Our facility in Charmhaven has been operating since the early 1990s and produces made-to-order decorative cabinet doors and panels for use in residential and commercial joinery. This facility uses advanced, automated manufacturing, including a robotic vertical storage system for produced doors and panels. Charmhaven is also accredited as a renewable energy power station with 4,700 solar panels, producing about 1,660 MWh per year, which covers ~35% of its energy requirements.

At our Stockyard facility in Gosford, we produce a range of made-to-order compact laminate products for use in benchtop, countertop, and toilet partition applications. It also manufactures custom cabinet doors for use in alfresco environments, as well as aluminium frame glass doors.